FurseWELD

Brand

FURSE

Technical Specification

The FurseWELD process

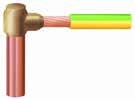

FurseWELD is a simple, self-contained system that uses the high temperature reaction of powdered copper oxide and aluminum, within a mold, to form permanent electrical connections.

Typical applications include:

- Earthing for power plants and substations

- Telecommunications

- Transmission and power distribution lines

- Cathodic protection

- Rail connections

The FurseWELD system:

- Requires no external power or heat source

- Creates high quality electrical connections

- Completely portable

- Can be used safely with minimum training

- Cost effective

- Can be used for over 45 standard connection configurations

The FurseWELD connection

FurseWELD connections have several advantages:

- Tolerant to repeated fault currents

- Highly conductive

- Does not loosen

- Excellent corrosion resistance

Most FurseWELD connections have at least twice the cross-sectional area of the conductors being joined, and an equivalent or greater current carrying capacity. Corrosion resistance is exceptional because of the very high copper content (> 90%) of the alloy.

Overview & Usage

FurseWELD exothermic welding is a cost-efficient method of making large or small numbers of high-quality electrical connections.